In today’s fast-changing world of manufacturing, repmold is becoming an exciting solution that is used in various industries and shaping future production lines. Instead of relying only on old methods, repmold combines industrial design innovation with rapid tooling solutions to create faster, smarter, and more reliable results. It plays a big role in the digital transformation in manufacturing, giving businesses more flexibility and helping them stay ahead in competitive markets.

What makes repmold stand out is how it improves both speed and quality. From prototype development trends to next-gen production systems, this technology supports modern industrial workflows and ensures companies save time and resources. The impact on the U.S. manufacturing sector is already visible, as more factories explore new ways of transforming how products are made. Simply put, repmold is not just a tool—it’s a step toward the future of production.

What is Repmold?

To put it defined in simple terms, repmold is a modern approach to mold-making that blends speed, precision, and flexibility. While the origin of mold-making methods dates back thousands of years, repmold represents the next big step in the evolution of production techniques. It moves us from traditional to digital molds, giving industries a way to design and manufacture with accuracy that was once impossible.

If we look at the historical background of molding, early artisans relied on clay, stone, and metal to create the first molds. These served as the conceptual foundation of molding, shaping tools, weapons, and everyday objects. Over time, industrial revolutions pushed the limits of what molds could do, leading to industrial heritage and innovation in steel, plastic, and composite manufacturing.

The symbolic shift from traditional vs. modern mold design highlights not just better tools but also smarter ways of thinking. Today, repmold is more than a technical upgrade—it represents roots of mold-making innovation combined with manufacturing terminology explained in a way that businesses can actually apply. By following the mold evolution timeline, we can see how repmold fits naturally into the long journey of making production faster, cheaper, and more adaptable.

How Repmold Works – The Process Explained

Repmold may sound complex, but the workflow is surprisingly straightforward. At its core, the process is designed to move ideas from concept to reality in a smooth, cost-effective way. Below, we’ll break it down step by step.

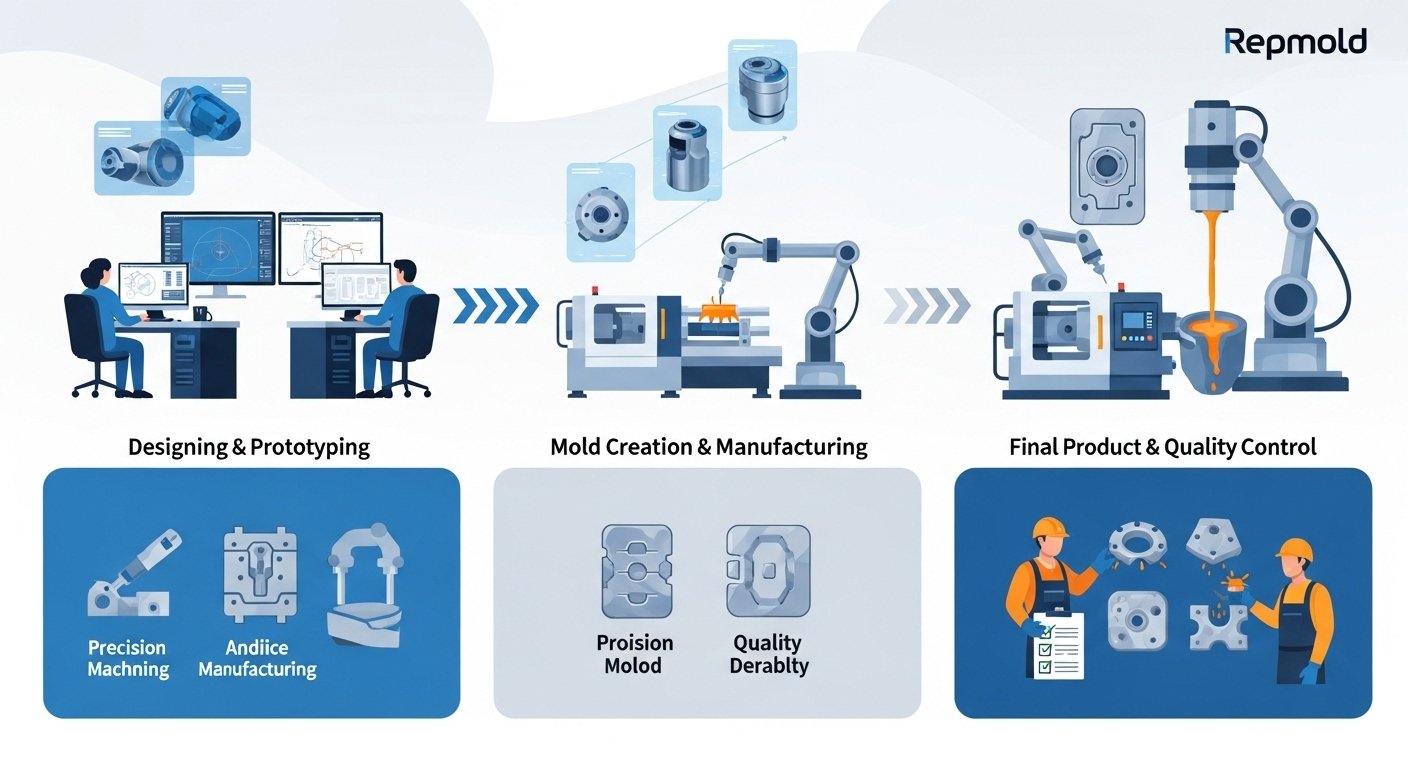

Designing and Prototyping

The journey begins with early-stage product design where engineers use 3D modeling software and a CAD design workflow to bring ideas to life. Instead of jumping straight into expensive production, they rely on virtual prototyping methods and computer-aided engineering to test functionality before a single mold is made.

This stage is about turning ideas into testable models. Designers create digital blueprints and run design validation tools to check for strength, flexibility, and overall usability. Through rapid concept testing and digitally simulating the product, companies can spot errors early and save both time and money. Essentially, it’s like prototyping before production, which helps in streamlining concept approval for stakeholders and clients.

Mold Creation & Manufacturing Steps

Once the design is ready, the next stage is actual production. The process typically begins with mold material preparation, ensuring the right balance of durability and cost. From there, teams follow a step-by-step mold creation process that may include casting and tooling methods, machining, or additive techniques.

During this stage, injection molding cycles are carefully managed, and casting and curing explained to ensure molds hold up under high-volume production. To guarantee product reliability, strict production quality checks and durability testing are performed at each stage. This is part of quality control in mold-making, ensuring accuracy down to the smallest detail.

After the initial run, post-production finishing polishes the product and prepares it for use. By following a defined fabrication sequence and standardized manufacturing workflow stages, businesses can produce high-quality parts consistently, whether for cars, electronics, or medical devices.

Key Technologies Driving Repmold

Behind every successful repmold project are powerful innovations that make it possible to design, test, and produce at an unmatched pace. Modern manufacturers rely on cutting-edge digital tools and next-gen factory technologies to turn complex ideas into real-world products. These technologies are not just upgrades—they are the backbone of today’s competitive production landscape.

One major driver is automation in production, which is all about automation improving consistency and reducing errors. With robotics integration, tasks that once required hours of manual labor can now be completed with speed and accuracy. Imagine robotic arms working alongside engineers, integrating robotics with molding to ensure every product is identical in quality.

Another big leap forward comes from AI-driven design and digital twin technology. These allow engineers to build virtual replicas of molds, run stress tests, and optimize designs before creating the physical version. The role of CAD and CAM software is critical here, as it links design directly to manufacturing, ensuring smooth transitions from idea to execution.

Material science is also advancing quickly. Companies are now using advanced composites and materials engineered for durability, making molds stronger yet lighter. Pair that with additive manufacturing synergy (like 3D printing combined with molding) and CNC machining tools, and businesses gain flexibility that was unthinkable just a decade ago.

Finally, all of this comes together in smart factory systems. These connected ecosystems monitor production in real time, predict maintenance needs, and keep workflows efficient. The result? A streamlined, intelligent, and highly adaptable approach that makes repmold one of the most reliable tools in modern manufacturing.

Benefits of Repmold Technology

Faster Production & Efficiency

One of the biggest reasons companies adopt repmold is speed. With reduced lead time and rapid manufacturing cycles, businesses can move from concept to finished product in record time. This means accelerated product launches and the ability to respond quickly to market demand. By shortening development cycles and saving valuable production hours, repmold helps manufacturers stay ahead of competitors.

A streamlined production workflow also boosts factory productivity. For example, an electronics company using repmold can design, test, and mass-produce new components weeks faster than with traditional methods. That time-to-market advantage is often the difference between leading the industry and falling behind.

Cost-Effectiveness

Efficiency isn’t just about time—it’s also about money. With lower production expenses and affordable tooling options, companies can scale without breaking the bank. Repmold reduces waste, optimizes material use, and cuts down on extra labor. This leads to material cost savings and efficient resource allocation across the entire workflow.

For businesses, this translates to helping companies save money, reducing long-term expenses, and achieving a better ROI for manufacturers. By making production more affordable, repmold ensures even small companies can compete with larger players.

Precision & Customization

Modern industries demand more than just speed and cost savings—they need accuracy and flexibility. With high-tolerance molding and precision engineering tools, repmold ensures every part meets strict quality standards. At the same time, it allows for tailored product solutions and fine-detail manufacturing.

Whether it’s customized product designs for healthcare devices or creating unique product molds for automotive parts, repmold delivers. It enables personalized manufacturing output, meeting exact client requirements, and achieving tight tolerances that traditional processes struggle with.

Sustainability & Reduced Waste

Today’s businesses must balance performance with responsibility. Repmold supports eco-friendly manufacturing by focusing on green production practices and recyclable materials. Its energy-efficient molding methods and sustainable supply chain benefits are major selling points for industries looking to reduce costs and meet environmental standards.

By reducing environmental footprint and minimizing material waste, repmold directly contributes to adopting cleaner production methods. From using sustainable raw materials to supporting green initiatives, this technology helps companies stay compliant with regulations and appeal to eco-conscious consumers.

Applications of Repmold Across Industries

The versatility of repmold makes it a game-changer across multiple industries. From transportation to healthcare, companies are using this technology to design faster, produce smarter, and innovate in ways that were once difficult with traditional methods. Let’s explore how repmold is reshaping different sectors of the economy.

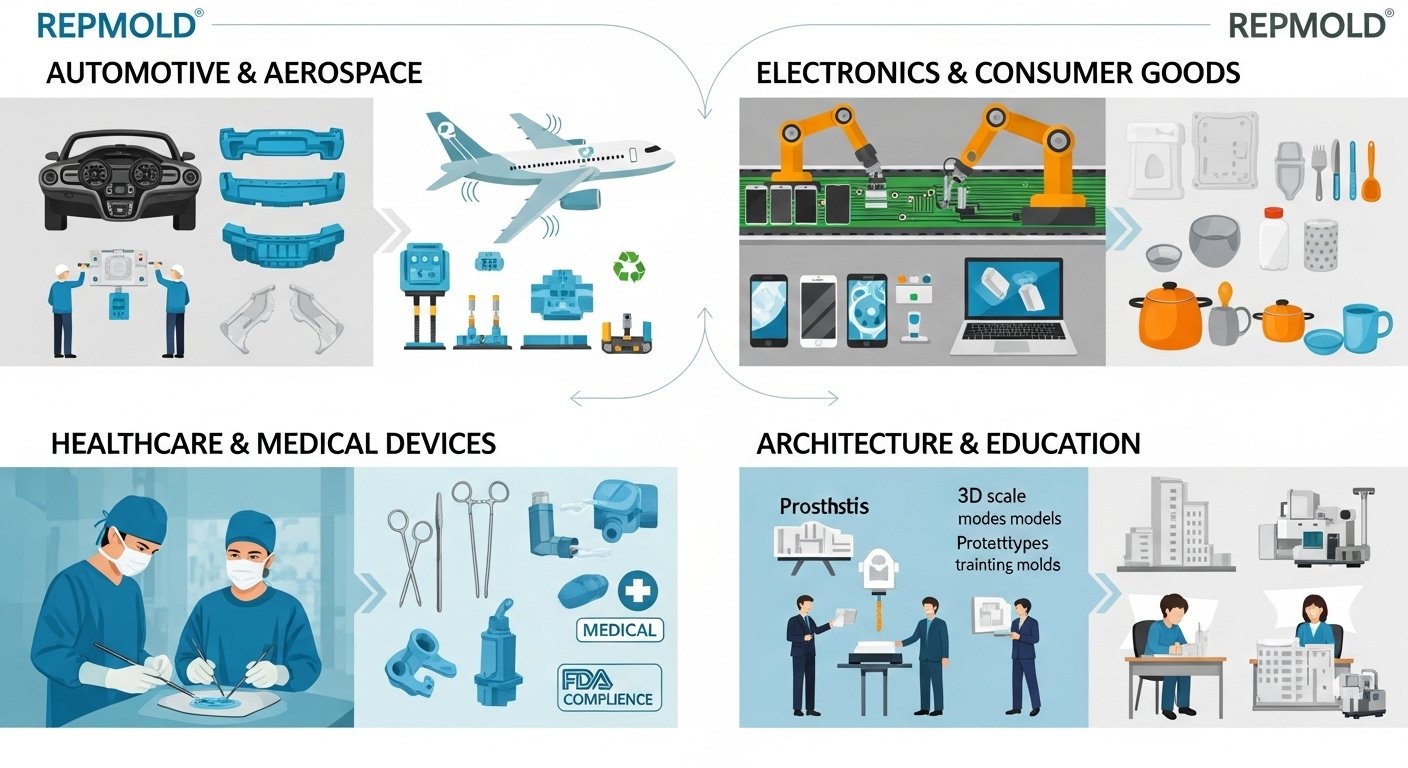

Automotive & Aerospace

The automotive and aerospace sectors depend heavily on precision, durability, and innovation. With repmold, manufacturers can work with lightweight materials to reduce vehicle weight and improve fuel efficiency without sacrificing strength. For example, it’s widely used for car parts manufacturing, including dashboards, bumpers, and interior fittings, where both performance and design matter.

In aerospace, custom tooling for aircraft and aircraft component molding allow engineers to create parts that enhance aerodynamics in design while meeting strict safety compliance parts standards. By ensuring durability in vehicles and supporting aerospace innovation, repmold provides industries with tools that boost reliability and performance in environments where safety is non-negotiable.

Electronics & Consumer Goods

In today’s tech-driven world, repmold plays a key role in the production of everyday items. It is applied in smartphone casings, laptops, and other plastic casings for electronics, ensuring products are durable yet stylish. Manufacturers also benefit from small-scale precision molding for components like circuit housings and connectors.

For large-scale production, mass production for electronics is made easier with high-volume production runs that maintain consistent quality. Beyond gadgets, repmold is equally valuable in shaping household products—from kitchenware to personal care tools. By supporting consumer tech innovation and improving product aesthetics, it enables brands to deliver functional and visually appealing goods at scale.

Healthcare & Medical Devices

Few industries demand as much accuracy as healthcare. Repmold is widely used in medical equipment such as surgical tools and testing devices, where biocompatible materials and sterile production environments are essential. Manufacturers rely on this technology for surgical instrument molding and manufacturing precision implants that must align with compliance with medical standards like FDA regulations.

It also supports prosthetic design innovation, creating safe materials for healthcare solutions that directly impact patient well-being. From supporting patient care devices like inhalers to producing custom-fit prosthetics, repmold ensures every detail meets the highest standards of reliability.

Architecture & Education

In architecture and education, repmold shines as a tool for creativity and learning. Architects using molds for planning can design architectural scale molds to help visualize building designs before actual construction begins. These creative design structures allow for better collaboration with clients and teams.

In classrooms, repmold is valuable for teaching students with prototypes and developing training prototypes that make lessons more engaging. From educational use of mold technology in engineering programs to learning through hands-on models, it empowers future innovators with practical tools to understand design and production better.

Business Impact – How Companies Can Leverage Repmold

For businesses in competitive industries, repmold is more than a manufacturing tool—it’s a strategic asset. By adopting this technology, companies can unlock competitive advantage and improve every stage of production. One of the most powerful aspects is workflow optimization, where complex steps are simplified, and teams can produce faster without sacrificing quality. This shift aligns closely with lean manufacturing principles, ensuring resources are used efficiently and waste is reduced.

When it comes to growth, repmold allows organizations to scale production smoothly. For example, a company can start with small prototype runs and then expand into mass production without needing to redesign the entire system. This flexibility supports market adaptability, helping businesses pivot quickly when consumer preferences or industry standards change. By following smart strategies for implementation, manufacturers can use repmold for driving business growth, enhancing supply chain efficiency, and finding new ways to reduce operational costs. In short, it provides a pathway for staying ahead of competitors in industries that evolve at lightning speed.

Challenges and Considerations

Like any advanced technology, repmold comes with challenges that businesses must address. The most common barrier is the high upfront investment, as adopting new systems requires capital for equipment, software, and training. Another hurdle lies in technical workforce needs. Teams must be trained to operate, maintain, and adapt to new systems—something that takes both time and resources.

Material availability is also a concern. Some projects may face issues with limited raw materials, making sourcing difficult for certain industries. In addition, the technology can involve maintenance complexity, which requires regular checkups and skilled support staff. Companies must also plan for production scalability issues, ensuring they can grow without bottlenecks or inefficiencies.

From a strategic point of view, firms must consider barriers to entry for companies, overcoming learning curves, and managing production risks. There are also broader navigating ethical dilemmas, such as balancing automation with workforce impact. Ultimately, businesses need to carefully weigh the pros and cons of adoption before committing to large-scale implementation.

The Future of Repmold

Looking ahead, the potential of repmold is enormous. With predictive manufacturing trends shaping industries, companies will rely on data and AI to forecast demand and optimize production. AI-powered mold design is already being tested, where artificial intelligence helps engineers create smarter, more efficient molds. Alongside this, smart materials innovation will lead to stronger, lighter, and more sustainable products.

Another exciting direction is the 3D printing integration with repmold. By combining additive and traditional methods, manufacturers can enjoy the best of both worlds—speed and precision. This aligns with the global push toward a circular economy impact, where waste is minimized, and materials are reused. In this future, companies will rely heavily on future-ready manufacturing methods, sustainable materials on the rise, and the adoption of artificial intelligence to keep up with global demand.

Simply put, when we ask “what’s next for mold technology,” the answer lies in smarter, greener, and more adaptable solutions. Repmold is not only shaping tomorrow’s industries but also helping manufacturers move toward a more sustainable and efficient future.

FAQs About Repmold

What is repmold in simple terms?

Repmold is a modern manufacturing approach that creates high-quality molds faster and with better precision. Unlike older systems, it uses advanced tools and digital workflows to reduce errors and improve efficiency. This makes it a popular choice for industries looking for reliable and cost-effective solutions. Here, you’ll find frequently asked queries answered in a clear way.

How much does repmold cost for businesses?

The cost of repmold depends on project size, materials, and design complexity. While the affordability factors vary, many companies find it cheaper in the long run because it reduces waste, speeds up production, and lowers maintenance. Businesses should see it as an investment rather than an expense, especially if they need fast product launches.

Which industries benefit most from repmold?

Repmold is used in various industries like automotive, aerospace, healthcare, and consumer goods. It helps car makers build lightweight parts, supports best-use scenarios in medical device manufacturing, and ensures electronics companies get precise casings. Overall, industries that require speed, accuracy, and scalability gain the most benefits.

Is repmold safe for production use?

Yes, repmold is safe and widely adopted by manufacturers worldwide. It follows strict safety compliance standards and ensures durable, high-quality results. Since it reduces human error through automation, it often improves workplace safety. Companies just need proper training and quality checks to get the most secure outcomes.

How does repmold compare to old methods?

Compared to traditional molding, repmold offers faster turnaround, higher precision, and less waste. It bridges the gap between misconceptions in mold-making and real performance by using differences from traditional molding like digital designs and automation. Simply put, repmold is a modern upgrade that delivers more value for both small and large-scale production.

What are some misconceptions about repmold?

One common myth is that repmold is too expensive for small businesses. In reality, its affordability factors and flexibility make it suitable for many scales of production. Another misconception is that it only works for large factories, but even startups can use it for rapid prototyping and efficient product testing.

When is repmold the best solution?

Repmold works best when speed, customization, and accuracy are priorities. For example, it’s ideal in best-use scenarios like producing medical implants, creating aircraft components, or launching new consumer gadgets quickly. If your goal is faster delivery and reduced costs, repmold is the smarter choice compared to older methods.

Conclusion

As we wrap up, it’s clear that repmold is more than just a manufacturing tool—it’s a catalyst for progress across industries. From faster production to precision design, the key points to remember are its ability to reduce costs, improve efficiency, and open doors to endless innovation. For decision-makers, these are important takeaways for manufacturers who want to stay ahead in today’s competitive market.

The final industry insights point toward a future where repmold plays a central role in shaping products, streamlining workflows, and driving smarter supply chains. With a clear innovation roadmap and a long-term vision, companies that embrace this technology will benefit from growth, adaptability, and sustainability.

In short, the importance of adopting modern methods like repmold cannot be overlooked. It offers a strategic adoption summary that encourages businesses to act now, experiment, and invest in smarter solutions. These final thoughts on industry impact show that repmold is not only transforming how things are made today but also looking forward to future growth that defines tomorrow’s manufacturing world.